I sometimes attend product development meetings at Isotopx. The subject of instrument design, by which I mean the “aesthetic values” of our products are quite often a subject of discussion. If you know your historic isotope ratio instruments, you’ll know that until relatively recently they been a triumph of function over form, with sometimes an almost wilful lack of design behind them. Just look at a TIMS instrument from the 1980s and 1990s and you’ll know what I mean. In this era, the more stainless steel on show, the better, and the more dial and knobs the better too. The manufacturers assumed the users preferred it like this, and in many cases they probably did.

The earliest examples I can think of that really bucked this trend (at least for the larger isotope ratio instruments) and covered up all of the stainless steel were the Thermo Scientific Neptune and the VG Axiom, both children of the 1990’s. Yet the reasons behind the designs were remarkably different. The Neptune was a multicollector ICP-MS, and you may know that such instruments extract the ions for analysis either by floating the interface region to high voltage (and “pushing” them out) or floating the analyser region to high voltage (thereby “pulling” the ions out). A comparison of those two techniques might be a good future blog, so watch this space.

The Neptune was designed using the latter technique, meaning that for safety reasons the whole of the instrument analyzer (in reality most of the instrument) was covered with panels. This did give the instrument a unique aesthetic, and it would have been easy to believe that this was design-driven rather than function-driven.

The VG Axiom was also a multicollector ICP-MS, but in this case the front end (interface region) was floated to high voltage, meaning that the rest of the instrument was at ground potential – no need to cover that lovely stainless steel in panels. Yet that’s exactly what VG did. The instrument was totally covered in made-to-measure fiberglass panels, designed to make the instrument look like something from the near future, which at the time it did! Comparisons were drawn between the VG Axiom and certain high-speed trains, a comparison that still stands up well today.

I was around at the time of the Axiom development program, and a challenge for such an instrument clothed in panels with heat extraction. Although the rear of the instrument was fitted with a battalion of heat-extracting fans, it got pretty warm under the panels. Hot fiberglass has a very distinctive (and not hugely peasant) smell, originating from the resin that binds the fibers. I worked for several years with this smell constantly in the air, I’m sure if I smelled it today it would transport me right back to the Axiom test floor at the VG Elemental factory.

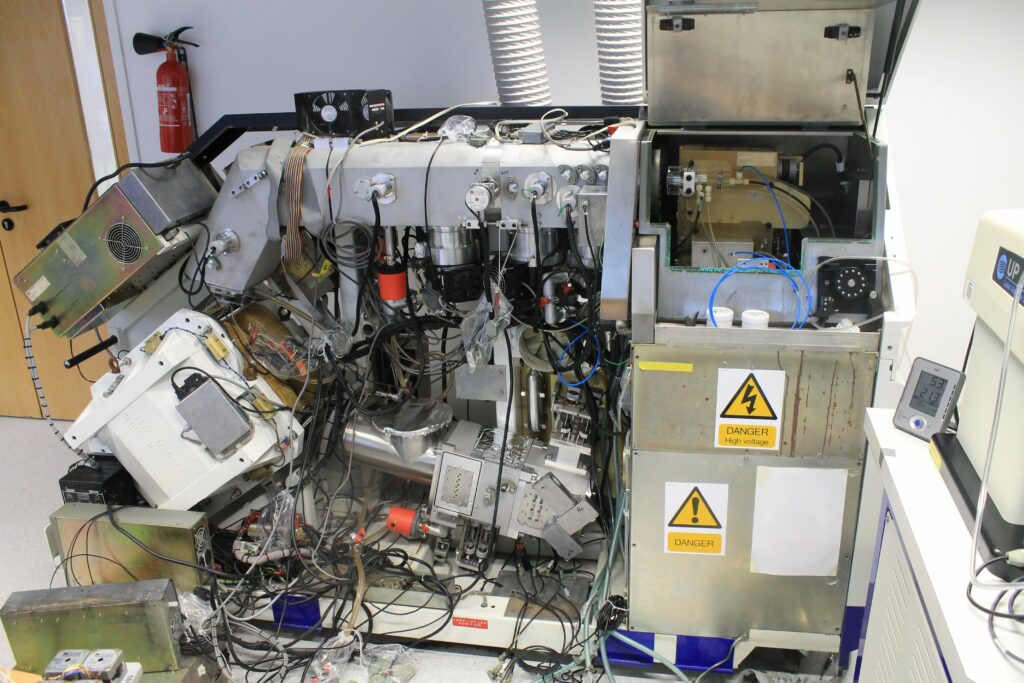

To counteract the risk of overheating, and also heat-related data drift (not to mention the smell), users would take off the panels and leave them sulking in the corner of the lab (the panels, not the users). Thus, the striking and forward looking design was usually lost, leaving an exposed (and very busy-looking) nest of electronics components and feedthroughs.

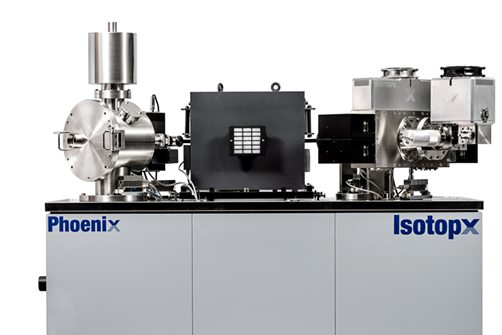

Since those days, the design of mass spectrometers of all kinds has moved towards sleek minimalism. As is often the case, this was led by the life sciences. This is due to several factors; firstly the real or perceived expectations of the customers (“they just want a black box”), and secondly the greater budgets available because of the number of units sold. In recent years this has filtered down to inorganic mass spectrometry – for example compare the current range of tripe quadrupole ICP-MS instruments from Agilent or Shimadzu with quadrupole ICP-MS from 20 years ago and the difference is stark.

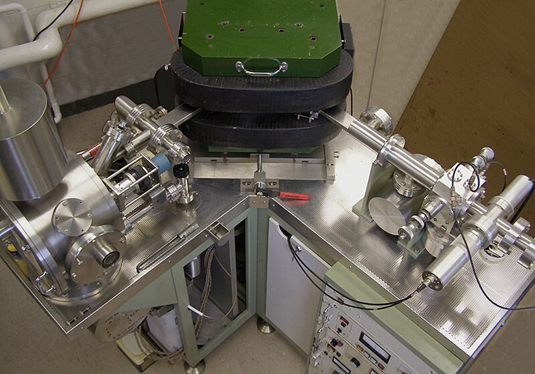

So is there any future for exposed stainless steel in analytical instruments? I think there is. I’m involved in regular customer demonstrations at Isotopx, and if there is one thing that these visitors have in common, it is that they like to be able to see “what’s what” in their instruments. Exposed flight tubes, recognizable magnet power supplies, they’re all well liked. And although we may have to choose to “cover up” certain future products, we’re in no hurry to cover up the stainless steel in our TIMS and noble gas mass spectrometers.

If you’ve got any thoughts about the look of modern isotope ratio mass spectrometers, please let me know, I’d be keen to hear (Stephen.guilfoyle@isotopx.com).