Zenon Palacz, Isotopx Ltd, Middlewich, Cheshire, UK

Introduction

Although Uranium lacks a stable isotope pair, a number of external techniques are available to correct for the mass fractionation that occurs during TIMS analysis.

The ‘gold standard’ methodology is to add a 233U-236U double spike to the sample and use this to calculate the mass fractionation. Whilst this produces the highest quality result it is costly and requires a relatively high level of expertise.

A simpler approach is to an external mass fractionation correction calculated from U standards which are run in the same batch as the samples. It is important that the filament load and isotopic composition of the standard is matched to the samples. It is also important that MS tuning parameters remain constant for both samples and standards. These factors make this a difficult process to automate but for a well designed experiment it is possible to routinely achieve a precision of ~ 0.05% (1 RSD) for 235U/238U.

A third approach is to use a total evaporation methodology. Here the temperature of the ionizing filament is kept constant whilst the current on the evaporating filament is steadily increased until the entire sample has evaporated. Summing ion intensities over the entire run will cancel out the mass fractionation error and allow an accurate determination of the isotopic composition.

Experimental

To evaluate total evaporation on a Phoenix TIMS, measurements were made on 200ng and 400ng loads of NBS U010 and NBL U030a, and 200ng of NBL U050.

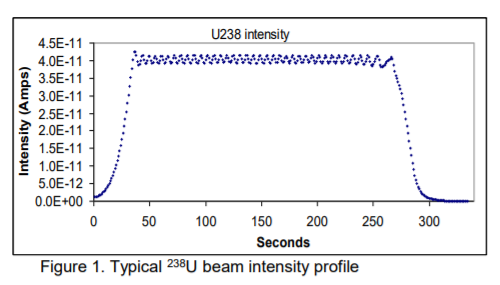

Before the evaporation process was started, an ion beam of 150mv 238U was focussed, optimized and peak centred. Baselines were taken for 60 seconds at +/-0.5amu. The evaporation process was then started. Following each 1 second integration the current on the evaporation filament was increased by 0.04A until an ion beam of 4V 238U was obtained. At this point the ion beam was held at 4V by increasing the evaporation current. A typical flat topped beam ion beam profile is obtained (Figure 1).

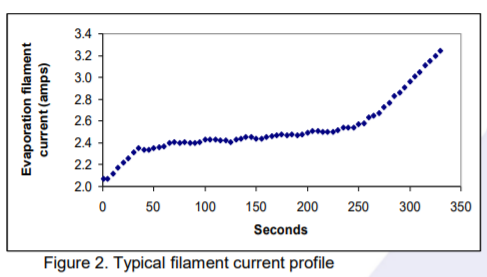

When the sample is almost consumed the filament current is increased again at 0.04A/sec (Figure 2), in an effort to keep the ion beam at the aiming intensity. This inevitably fails and data collection is terminated when the ion beam falls below 150mv and filament current moves above 3.3A.

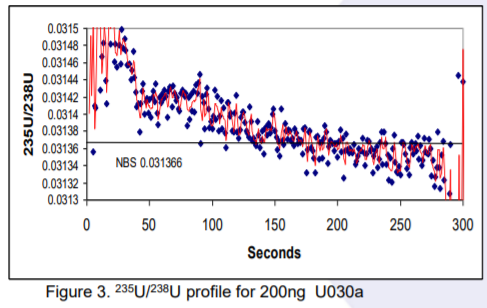

Figure 3, shows the behaviour of the 235U/238U ratio during the evaporation process. Starting and ending with scatter due to low intensity, the bulk of the measurement shows a gradual decrease in ratio from positive mass fractionation with a ratio greater than the certified value, to ratios less than the certified value at the end of the measurement.

Results

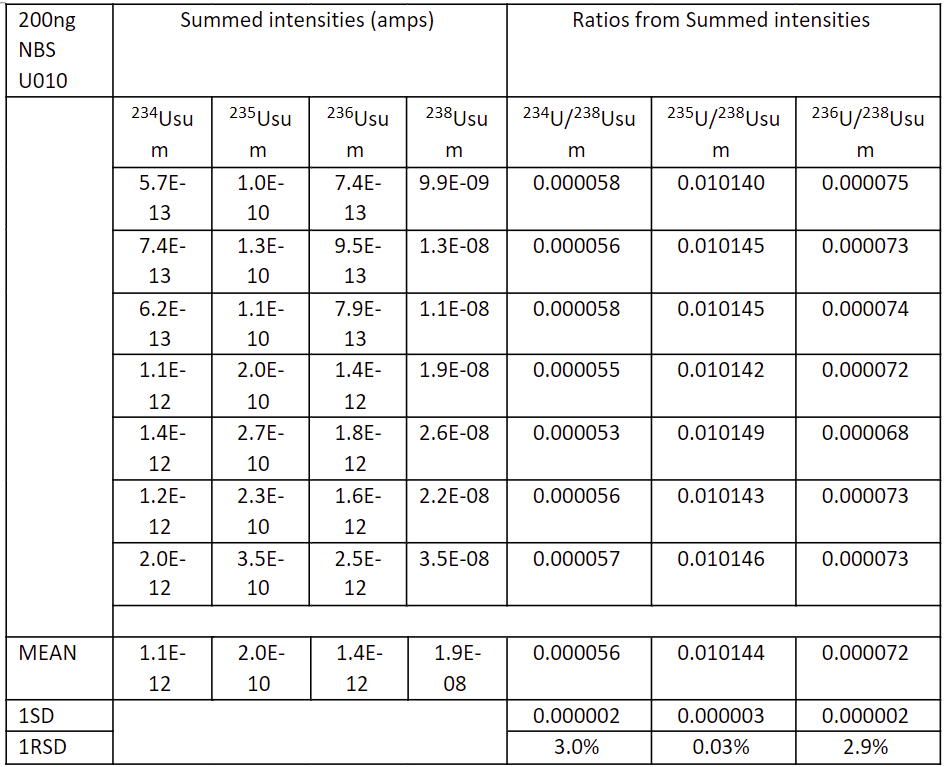

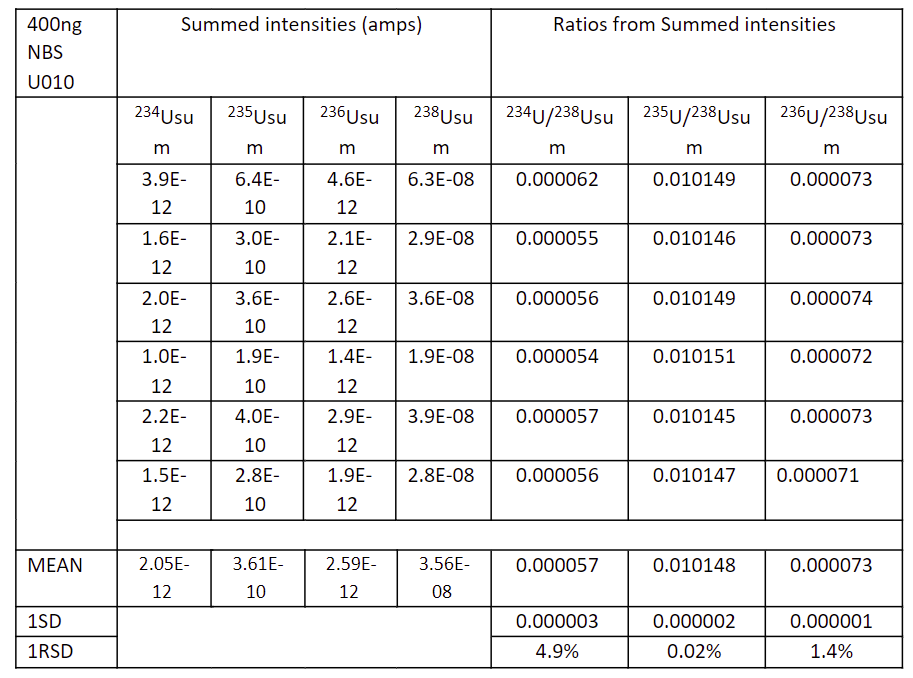

CRM U010 – Results for repeat analysis of 200ng and 400ng CRM U010 are shown in Table 1. The ratios are derived from the totally summed intensities obtained during the analysis.

The mean 235U/238U for 200ng of U010 is 0.010144 with a reproducibility of 0.03% 1RSD, and for the 400ng loads the ratio is 0.010148+/- 0.02% 1RSD.

Combining both sample sizes produces a mean value of 0.010146+/-0.03% 1RSD. The CRM value is 0.01014+/-0.1%. A residual bias between the measured and the certified value of 0.01014/0.010146 = 0.999413 can be calculated.

Results

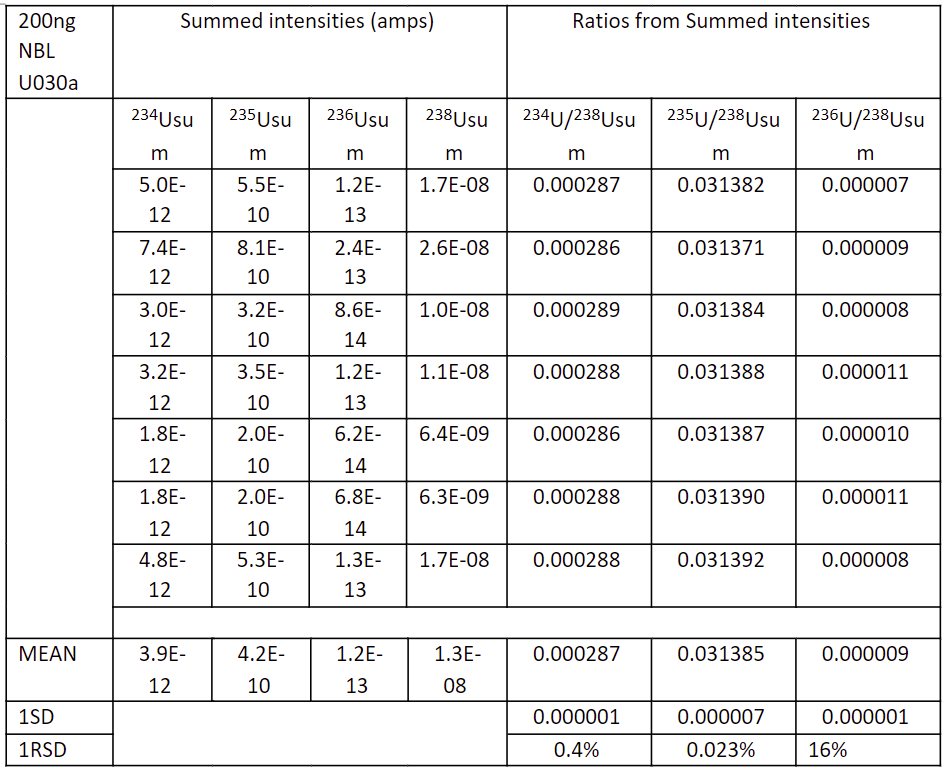

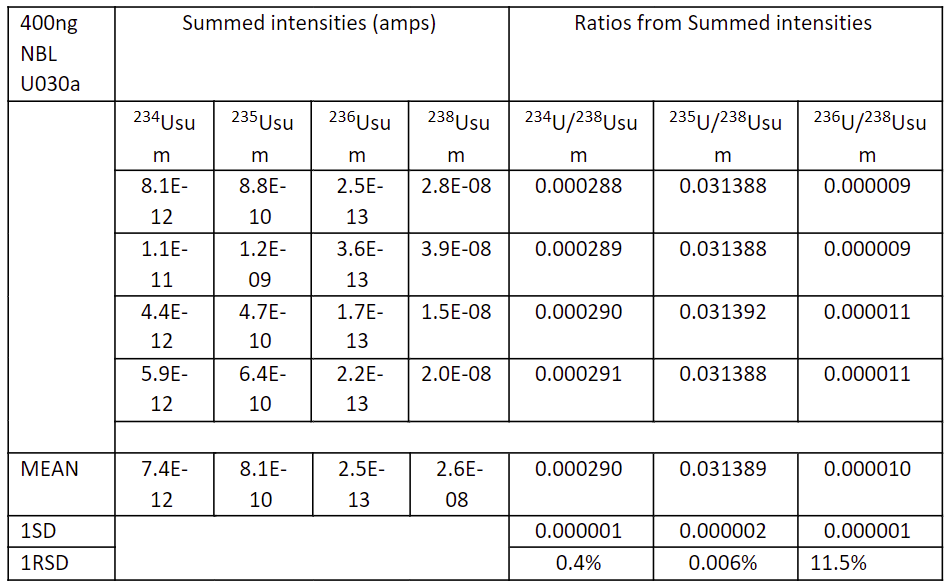

CRM U030a – Results for 200ng and 400ng CRMU030a are shown in Table 2.

For 200ng the mean 235U/238U of the summed intensities is 0.031385+/-0.023% 1RSD, and for the 400ng measurements 0.031389+/-0.006% 1RSD. Combining the two sample sizes produces a mean ratio of 0.031386+/-0.02% 1RSD.

Multiplying this value by the bias determined from the U010 data produces a ratio of 0.031368, which is identical within error to the certified value of 0.031367, it is also the same as that reported by Richter and Goldberg (2003) of 0.031369+/-0.009%, obtained by total evaporation on several microgram sized sample loads.

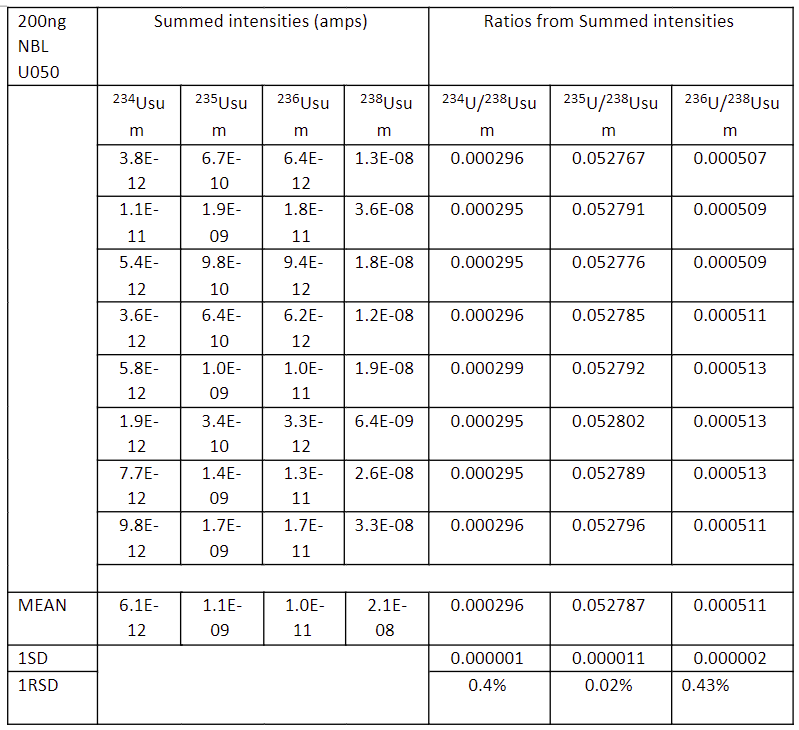

CRM U050 – 8 measurements of 200ng CRM U050 produced a mean 235U/238U of 0.052787+/-0.02% 1RSD.

Multiplying this value by the bias factor obtained from U010 produces a mean ratio of 0.052756. This is not the same as the certified value of 0.052784. It is however identical to the value of 0.052756 obtained by Richter and Goldberg (2003) on larger sample sizes. We can therefore confirm that the CRM value of 0.052784 for CRM U050 is probably not correct.

Conclusions

- Precision of 0.03% (1RSD) or better can be obtained by total evaporation on sample sizes of a few hundred nanograms. This is better than the external mass fractionation correction method.

- A small residual mass bias is present of about 0.06% for the 235U/238U, or 0.02% per mass unit, with the summed ratios being slightly higher than the certified value.

- The size of the residual bias increases very slightly with sample size.

- The residual mass bias appears consistent between U010 and U030a, and is therefore correctable

- The corrected 235U/238U for U050 is not within error of the certified value, but is consistent with the value obtained by Richter and Goldberg (2003) on a different type of TIMS.

Reference

Richter, S. Goldberg, S.A. 2003. Improved techniques for high accuracy isotope ratio measurements of nuclear materials using thermal ionization mass spectrometry. International Journal of Mass Spectrometry 229. 181- 197

Download Application Note

Download the complete Application Note: NBS U010, NBL U030a and NBL U050 uranium standards by total evaporation